Results of the environmental preservation activities

Measures against water contamination

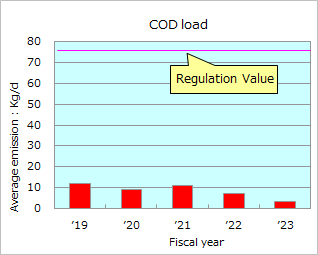

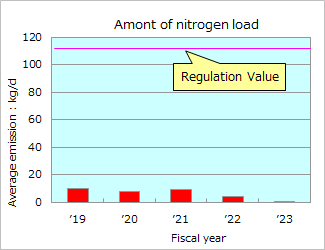

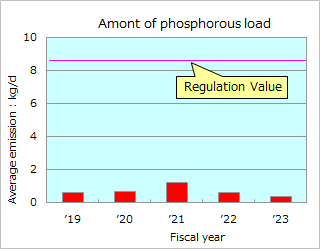

Yamaguchi Operations is striving to reduce the amount of water contaminants from the industrial effluent generated at its plants. We are successfully keeping the emission of COD (chemical oxygen demand), nitrogen and phosphorus within the agreed limits by treating effluent with a flocculation and sedimentation unit, and an activated carbon treatment unit.

-

Changes in COD(Chemical Oxygen Demand)load

-

Changes in nitrogen load

-

Changes in phosphorous load

Industrial waste and recycling measures

Yamaguchi Operations is working on the reduction of the amount of industrial waste, including by-products (waste oil), sludge, and waste metals, as well as recycling of them.

We reduce the final volume of waste to be disposed of by intermediate treatment (dewatering, incineration or other processes for reduction of waste volume) and recycling.

Chemical substances management

Released and transferred quantity of substances defined in the PRTR system (for the fiscal year 2023)

Yamaguchi Operations is making every effort to maintain/continue to improve proper and effective control of chemical substances by compiling and analyzing the data on the quantity of released and transferred PRTR-specified substances. The emission of benzene has been substantially reduced since two benzene tanks were converted to the inner floating roof-type tanks in 2006.

(Unit: t/year)

| Substance number | Substance name | Emissions into the atmosphere | Emission into the water bodies | Transferred quantity | Total |

|---|---|---|---|---|---|

| 53 | Ethylbenzene | 2.6 | 0.0 | 78.0 | 80.6 |

| 201 | 2,4-Dinitrophenol | 0.0 | 0.0 | 7.0 | 7.0 |

| 240 | Styrene | 0.4 | 0.0 | 33.0 | 33.4 |

| 300 | Toluene | 0.1 | 0.0 | 3.4 | 3.5 |

| 400 | Benzene | 0.7 | 0.0 | 0.9 | 1.6 |

- * If the total released and transferred quantity of a substance is below 0.1 t/year, the substance is omitted.

- (*)PRTR (Pollutant Release and Transfer Register) System

It is a system, put in force since April 2001, in which the quantity of chemical substances that are potentially harmful to human health and to the ecosystem and that are emitted into the environment or transferred as contained in waste out of a business establishment is reported to the government once a year. This data is published by the government.